|

|

|

||

|

||||

- The company’s activities are set out in the manual and ISO 9001 quality system, have undergone constant revision as part of continuous improvement, and receive periodical inspections by our clients and certifying organisations.

- Every item leaving the company is provided with a product certificate. This is a sort of ‘passport’ connected with the forging-batch code that every forging has stamped on it, enabling the product to be traced back to its origins and mechanical characteristics, anywhere and at any time. There are three types of certificate: 2.2 , 3.1 and 3.2. The first is general, the second includes the results of the tests carried out and the third is accompanied by the check-up of an external inspector. Certificates are saved on an online database which can always be consulted.

- Over many years of activity, Feat has accumulated hundreds of international standards which govern mechanical components in all their manifestations. This library of knowledge is kept up-to-date by means of an IT database.

- The respect for the environment is strictly linked to quality. That’s why we are adapting our structure to the ISO 14001 regulations, carrying out waste policies and developing systems for recovering the energy that the company produces by means of its own cogeneration plants.

- The preparation and professionalism of personnel and in-depth training are fundamental requisites when making high-quality products and creating a healthy and safe working environment. The essence of this principle is expressed in Feat Group’s ‘Ethics Code’.

- The philosophy of control must cover all stages of the production process. Each employee is responsible for his or her own work . Any examples of non-conformity must trigger action aiming to discover the causes, resolve the problems and avoid repetition.

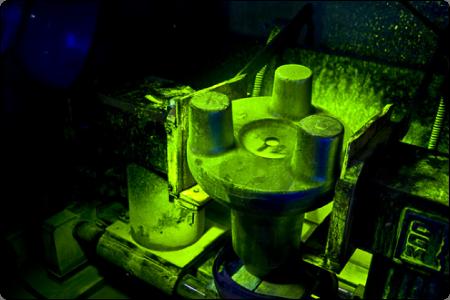

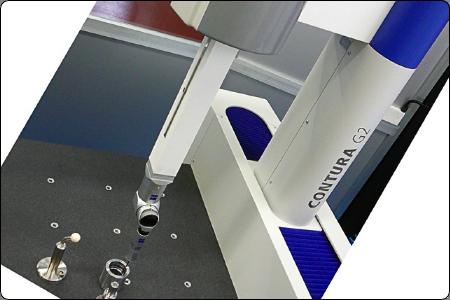

- Products are tested and checked according to applicable standards, clients’ requirements and their needs. Control equipment is regularly calibrated. The testing department can carry out all types of control which are non-destructive and inspectorial, in accordance with European or American standards.

- The laboratory carries out destructive tests and a metallurgist of the third level is available to analyse more complicated cases.

- Feat components are used in extreme applications and as safety elements. They are all covered by product insurance for damages and civil liability up to a value of 10 million euros, valid all over the world including the U.S.A.

- 30 years we are a qualified manufacturer of valve components for the nuclear sector. Accumulated experience meet French, American and Russian std. A manual regulates the activity in accordance with ASME BPVC.

|

Our commitment to keeping all our certifications up to date testifies to the high quality of our work and to the full respect of the existing regulatory framework. |

|||||

|

|||||

ISO 9001 |

ISO 14001 |

ISO 50001 |

ISO 45001 |

ISO 19443 |

HAF 604 |

Policy |

Nuclear Policy Rev 1 |

TUV PED+AD |

ABS HOOKS |

Lloyd Register |

Norsok |

DNV - GL |

ABS |

B.V. |

RINA |

ESG ECOVADIS |

Liability ACE |